News Center & Categories

DESIGN GUIDE

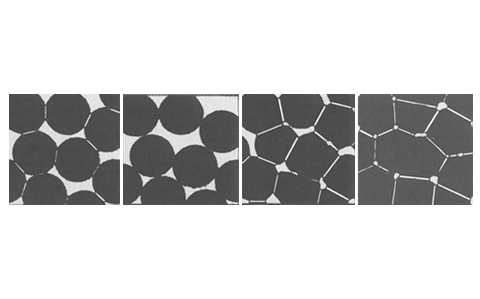

Designing components for MIM is more akin to designing for plastic injection molding than to designing for other metal-forming processes.

Designing components for MIM is more akin to designing for plastic injection molding than to designing for other metal-forming processes.

Tel.:+86-760-23453788 Fax.:+86-760-23453789 E-mail: sales@sintspm.com

Address: South Industrial Zone,Fusha Town,Zhongshan City,Guangdong Province,China

copyright@2007-2015@Zhongshan SintS Powder Metallurgy Co.,Ltd